About

What is hydraulic fracturing?

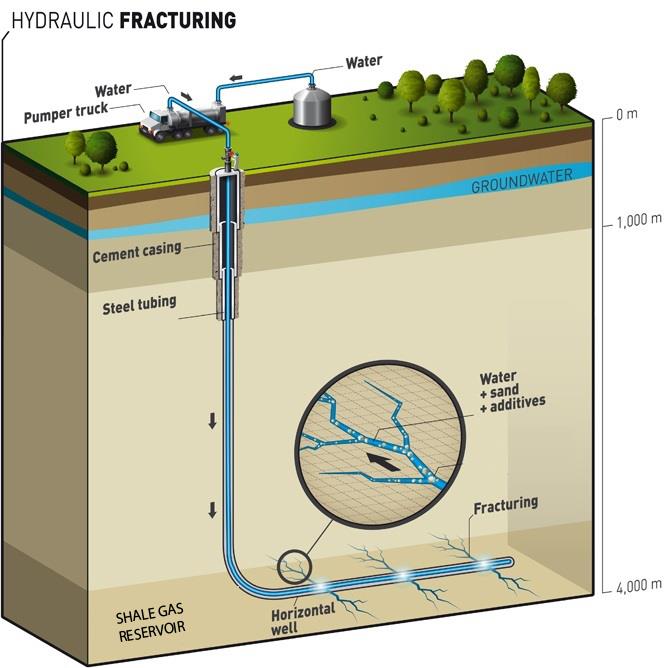

Before gas can be extracted from the shale gas reservoir, hydraulic fracturing must occur. Hydraulic fracturing is a technique used to enhance the production of the gas. Hydraulic fracturing refers to the injection of fluid (comprising approximately 99.5% water and proppant (sand) and approximately 0.5% chemical additives) at high pressure into targeted sections of the layers of gas-bearing rocks. This creates localised networks of fractures that unlock gas and allow it to flow into the well and up to the surface.

Figure 3: Schematic diagram of shale gas extraction process. Source: Modified from Total S.A.

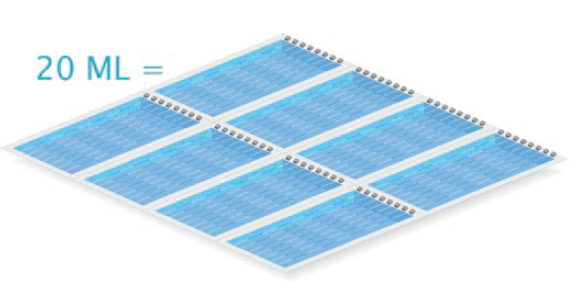

An average of about 20 to 30 megalitres (ML) of water is used per fracked horizontal well, which would fill approximately between 6 to 10 Olympic sized swimming pools.

Figure 4: 20 megalitres would fill approximately 8 Olympic sized swimming pools. Source: CSIRO Gas Industry Social and Environmental Research Alliance.

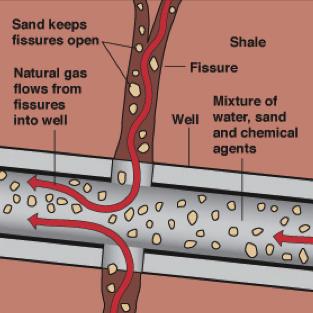

To prevent the fractures in the rock from closing, proppant is added to the fracturing fluid and remains in the fractures holding them open as shown in Figures 3 and 5.

Figure 5: Diagram of proppant in action. Source: Modified from Al Granberg.

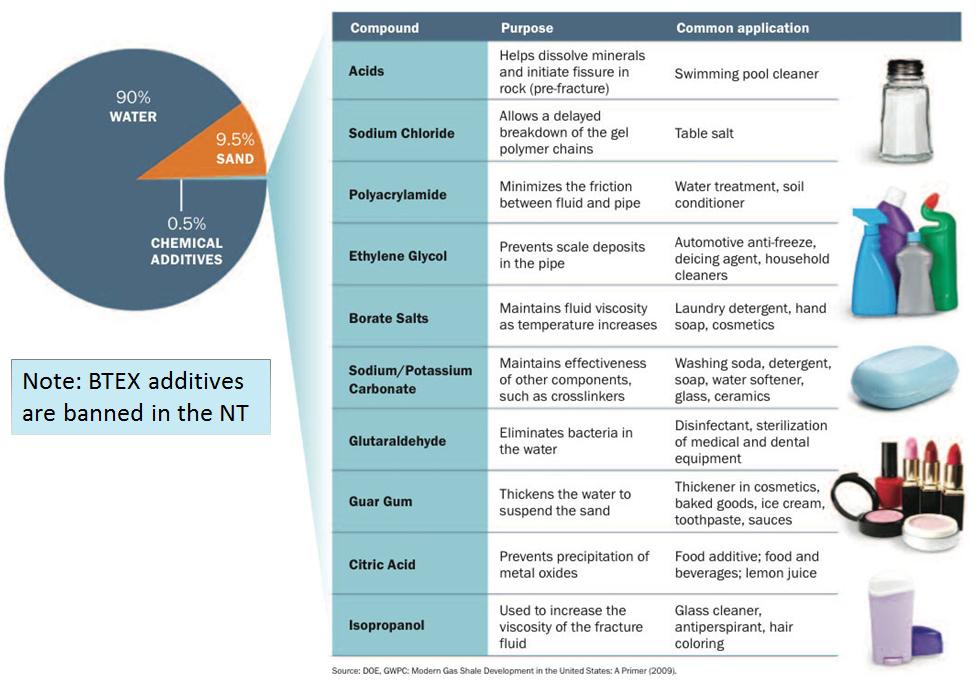

Chemicals used in hydraulic fracturing

Water and proppant make up around 99.5% of the hydraulic fracturing fluid. Added chemicals make up the other 0.5%. The following chemicals are commonly added to the water to perform the following functions (see Figure 6 below):

- a gelling agent, such as guar gum, is used to create a gel to suspend the proppant in the water and transport the proppant through the fracture

- a gel breaker, such as ammonium persulfate (used in hair bleach), that reduces the viscosity or thickness of the hydraulic fracturing gels so that they can transmit water, and gas surfactants, such as ethanol, together with a cleaning agent, in order to allow high pump rates and reduce pressure

- a bactericide or disinfectant, such as sodium hypochlorite (pool chlorine) and sodium hydroxide (used to make soap), to control bacteria growth in the well that contaminates the gas and restricts gas flow

- acids and alkalis, such as acetic acid (vinegar) and sodium carbonate (washing soda), to assist in the initiation of the fracture and improve fluid flow in the rocks.

Toxic BTEX chemical additives (benzene, toluene, ethylbenzene and xylenes) are banned in the Northern Territory for use in the extraction of unconventional gas.

Figure 6: Typical hydraulic fracturing fluid additives that may be used. Source: Modified from US Department of Energy, 2009, Modern Shale Gas Development in the United States: A Primer.

Additional information

To find out more about hydraulic fracturing, visit:

- About Shale Gas on the Scientific Inquiry into Hydraulic Fracturing in the Northern Territory website

- Onshore gas extraction (printable booklet) on the Our Territory Gas Strategy website.